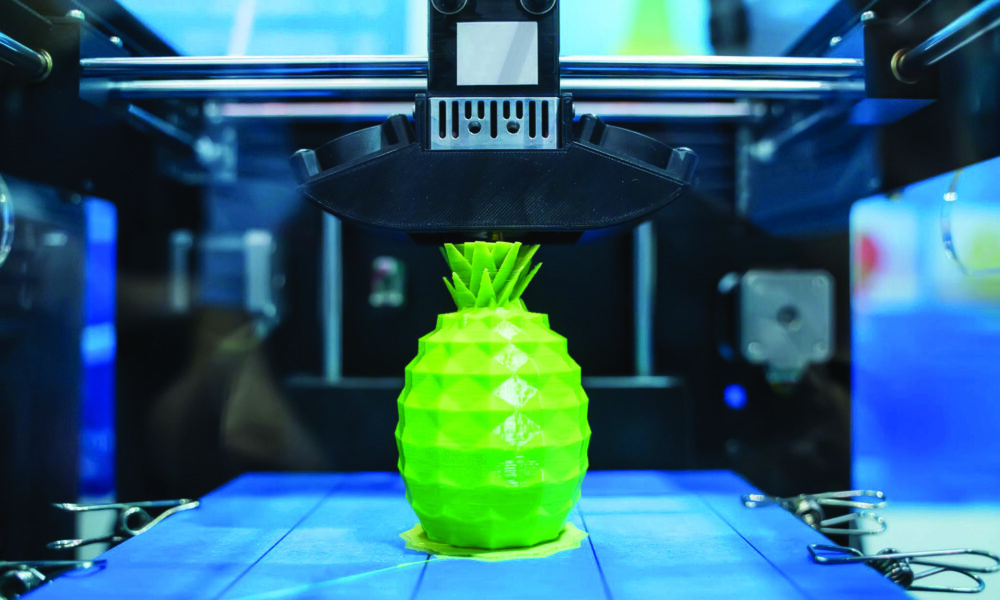

Three-dimensional printing (3D printing) feels like one of those buzzwords we heard all the time growing up; we were told that it would be revolutionary and change the world. But, in 2022, the media’s excitement has nearly disappeared. Surprisingly though, the 3D printing market is booming. In 2021, it was valued at over $13.84 billion USD and is expected to have an annual growth rate of over 20.8 per cent from now until 2030. Despite the industry’s success, the actual process of 3D printing remains mysterious to many.

How does it print?

The printing process all starts with the creation of a 3D model file. But you may be asking yourself, “where do I get one of these files? Do I have to make them myself? I have no idea how to do 3D modelling!”

Well, luckily for you, whatever item you would like to print has probably been designed and posted on a website like Thingiverse or Yeggi for free. If the design does not exist, computer-aided design (CAD) software such as AutoCAD can easily be used to create whatever you desire. Once a design has been finalized and the file is ready, it is imported into a slicing software like Ultimaker’s Cura. A slicing software, just as the name suggests, slices your model into thousands of tiny layers and preps it for the printer. With the file sliced and prepped, it is transmitted to the printer via USB, Wi-Fi, or a secure digital card.

Then, the printer heats up the substrate—the material used to physically build the model—to make it malleable and gets to work printing layer by layer. Acrylonitrile butadiene styrene (ABS) and polylactic acid are the most common substrates, but printing with metal is possible as well. Small projects can be completed within half an hour, but larger designs require over half a day.

What can 3D printing be used for?

The first thought that comes to mind when someone hears the word “3D printing” is probably tchotchkes and knick-knacks. But the printing possibilities are endless: From replacement parts for discontinued items to producing food and even designing homes.

In the medical sector, finding viable organs for transplant patients is a difficult and time-sensitive process, with 223 people in Canada dying while waiting for organs in 2018 alone. Luckily, 3D printing could revolutionize this with the rapidly evolving field of organ bioprinting. Organs aside, 3D-printed prosthetic limbs are more easily available because of their cheaper price and customizability. A standard prosthesis is prohibitively expensive for most, with even basic leg prostheses costing between $4,200 to $7,200. If someone wanted a highly advanced leg prosthesis, they could expect to pay at least $70,000 before insurance. Comparatively, a 3D-printed arm could be purchased for less than $400 and be manufactured within a day.

That manufacturing speed also works wonders in other sectors, such as prototype development. Hand-making a prototype out of carving foam or forming clay is both time-consuming and often inaccurate. With 3D printing, an engineer can design a prototype and print it initially with ABS. Once the kinks have been worked out, engineers can print with higher-quality materials such as titanium, stainless steel, and aluminum. Companies such as Black Diamond Equipment, which specializes in climbing, skiing, and mountain gear, have used 3D printing to produce prototypes at a fraction of the previous cost.

Are there 3D printing services on campus?

If a student wants to try out 3D printing, they can request access to the Innovation Commons, located within the McLennan-Redpath library complex. The Innovation Commons has four printers and student assistants available throughout the week to help with projects.

There is also a student-run printing service called The Cube—a subset of the Engineering Undergraduate Society. A student can send in a request along with their file and desired substrate and receive a quote. So if a student has no desire to book a printer and deal with perfecting their project, they can have one of The Cube’s technicians do it for them.